The Anesthesia Gas Machine 2026

Michael P. Dosch PhD CRNA (ret), Darin Tharp CRNA MS

University of Detroit Mercy - Nurse Anesthesia

This site is https://healthprofessions.udmercy.edu/academics/na/agm/.

Revised Feb. 2026

The Anesthesia Gas Machine 2026

Michael P. Dosch PhD CRNA (ret), Darin Tharp CRNA MS

University of Detroit Mercy - Nurse Anesthesia

This site is https://healthprofessions.udmercy.edu/academics/na/agm/.

Revised Feb. 2026

Vapor pressure- Molecules escape from a volatile liquid to the vapor phase, creating a "saturated vapor pressure" at equilibrium. Vapor pressure increases with temperature. Vapor pressure is independent of atmospheric pressure, it depends only on the physical characteristics of the liquid, and its temperature. So, even although evaporation proceeds at a rate governed by liquid temperature and is independent of altitude (barometric pressure), individual vaporizer types may or may not function the same at altitude.

Latent heat of vaporization- Just as our skin cools when we step out of the shower, the temperature of the remaining liquid will drop as vaporization proceeds, lowering vapor pressure, unless this is prevented. The latent heat of vaporization is the number of calories needed to convert 1 g of liquid to vapor, without temperature change in the remaining liquid.

Specific heat- is the number of calories needed to increase the temperature of 1 g of a substance by 1 degree C. Manufacturers select materials for vaporizer construction with high specific heats to minimize temperature changes associated with vaporization.

Thermal conductivity - a measure of how fast a substance transmits heat. High thermal conductivity is desirable in vaporizer construction.

Please take the time to read these sections of How Equipment Works. Don't let the cartoonish illustrations fool you- the author has a deep understanding and a great ability to explain these concepts.

Dräger Vapor 2000 & 3000, Aladin vaporizers (Aisys), and Tec 7 (and older vaporizers Dräger Vapor 19.1, Penlon Sigma, Tec 4 & 5,) are classified as

The copper kettle and Vernitrol (strictly museum pieces at this point) are measured-flow, bubble-through, non-temperature compensated, multiple agent, and out of circuit.

The Tec 6 desflurane vaporizer is not a variable bypass vaporizer, it is an injector (i.e. gas-vapor blender).

| Classification | Variable bypass (e.g. Tec, Aladin, Vapor 2000) |

Injector (e.g. Tec 6, A9, Flow-i) |

| Splitting ratio (carrier gas flow) | Variable-bypass (vaporizer determines carrier gas split) | Dual-circuit (carrier gas is not split) |

| Method of vaporization | Flow-over (including the Aladin for desflurane, which does not require added heat like the Tec 6) | Injector (gas/vapor blender): vapor is injected into fresh gas flow |

| Temperature compensation | Automatic temperature compensation mechanism | Tec 6 is Electrically heated to a constant temperature (39ºC; thermostatically controlled) |

| Calibration | Calibrated, agent-specific | Calibrated, agent-specific |

| Position | Out of circuit | Out of circuit |

| Capacity | Aladin: 250 mL | Tec 6: 390 mL |

The vaporizer interlock ensures that

|

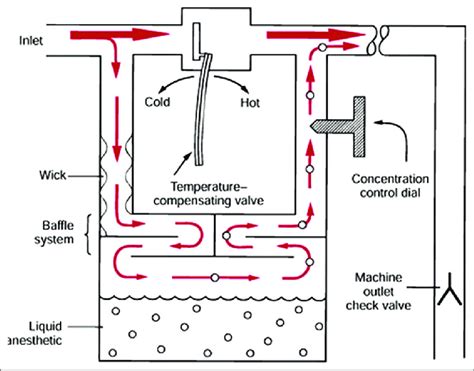

Variable bypass- principle. Click on the link to see the larger version. |

Splitting ratio Total fresh gas flow (FGF) enters and splits into carrier gas (much less than 20%, which becomes saturated with vapor) and bypass gas (more than 80%). These two flows rejoin at the vaporizer outlet. The splitting ratio of these two flows depends on the ratio of resistances to their flow, which is controlled by the concentration control dial, and the automatic temperature compensation valve.

Effect of flow rate: The output of all current variable-bypass vaporizers is relatively constant over a wide range of fresh gas flows (250 mL/min to 10 L/min), due to extensive wick and baffle system that effectively increases the surface area of the vaporizing chamber. All sevoflurane vaporizers are (slightly) less accurate (due to the low vapor pressure of the agent) at high fresh gas flows (> 10 L/min) and high vaporizer concentration settings (8%) typical after induction, where they deliver less than the dial setting.[4]. Clinically this is relatively unimportant, since we titrate to effect (end tidal agent concentration) and use overpressure.

Effect of ambient temperature: The output of modern vaporizers is stable from 20-35 degrees C, due to

Effect of intermittent back pressure transmitted from breathing circuit: The pumping effect is due to positive pressure ventilation, or use of the oxygen flush valve. It can increase vaporizer output. Modern vaporizers are relatively immune due to check valves between the vaporizer outlet and the common gas outlet, smaller vaporizing chambers, or tortuous inlet chambers. Any of these design features prevent gas which has left the vaporizers from re-entering it.

The effect of altitude on vaporizer performance is controversial. Dorsch and Dorsch (Understanding Anesthesia Equipment 5th ed. 2008) state that one must consult the operator's manual for each model. Some sources state that variable bypass types need not be adjusted for moderate changes in barometric pressure, but the Tec 6 must be dialed up beyond the desired dose at higher altitudes. Other sources disagree. Note that nitrous oxide is less useful as altitude increases, since it becomes more difficult to supply adequate pO2 using N2O when total atmospheric pressure declines. Further reading here.[5], [6], [7].

|

Filling a keyed vaporizer. Click on the link to see the larger version. |

|

Filling a funnel-type vaporizer. Click on the link to see the larger version. |

For either funnel or keyed filler types, fill the vaporizer only to the top etched line within the sight glass. Do not hold the bottle up on a keyed filler until it stops bubbling (this will overfill the chamber, particularly if the concentration control dial is "on", or if leaks are present). While it has been stated that the Tec 6 Desflurane vaporizer is an exception, even that vaporizer is safer to fill in the "off" position. But why remember this particular exception? It's safe to fill any vaporizer only when it is "off."

How much liquid agent does a vaporizer use per hour? Modern workstations can measure and report the amount of liquid agent used for each case. It can be approximated using the formula given by Ehrenwerth and Eisenkraft (1993):

Or one can determine the volume (mL) of saturated vapor needed to provide 1% (ie 4000 x 0.01 = 40 mL); then use Avogadro's hypothesis, the molecular weight, the liquid density, and molar volume (22.4 L at standard temperature [0 degrees C] and pressure [100 kPa or 1 atm]) to determine how many mL of liquid become 40 mL vapor per minute. Typically, 1 mL of liquid volatile agent yields about 200 mL vapor. This is why tipping an older vaporizer is so hazardous- it discharges liquid agent into the control mechanisms, or distal to the outlet. Even minute amounts of liquid agent discharged distal to the vaporizer outlet result in a large bolus of saturated vapor delivered to the patient instantaneously.

Important safety features include:

|

Vapor 2000 (right). Click on the link to see the larger version. Vapor 2000 is a tippable variable bypass vaporizer (also applies to Aisys cassettes). The Vapor 2000 dial must first be rotated to a "T" setting ("transport" or "tip") which is to the right of zero in the figure. |

|

|

Vapor 3000. Click on the link to see the larger version. The Vapor 3000 is also tippable, otherwise it is a standard variable bypass vaporizer. |

|

Tec 7. Click on the link to see the larger version. The Tec 7 is a standard variable bypass vaporizer. |

|

Aladin vaporizer. Click on the link to see the larger version. Aladin vaporizer (Aisys) Cassettes containing liquid anesthetic are inserted into a port containing the central electronic control mechanism, which recognizes the contents of the cassette and permits fresh gas to flow over the liquid agent. Because each cassette is only a liquid sump without control mechanisms, they can be tipped in any orientation without danger, and they are maintenance free. The cassette and the control mechanisms are checked as part of the electronic equipment checklist daily. Aladin will not deliver volatile agent without electricity (main wall outlet power, or during battery backup) and adequate oxygen (or air) pressure. The output of older vaporizers varies slightly with changes in fresh gas mixture, whereas the Aladin compensates for this automatically. The cassettes are light and may be removed with one hand. The Aisys has low agent alarms on all vaporizers. This vaporizer's performance has been studied.[13] |

|

Flow-e vaporizers (seen just below the green breathing bag). Click on the link to see the larger version. |

|

Mindray A9 vaporizers. Click on the link to see the larger version. |

|

Tec 6 vaporizer. Click on the link to see the larger version. Tec 6 desflurane vaporizer: The saturated vapor pressure at room temperature (20 °C) is 664 torr (87% of one atmosphere). This means that desflurane is nearly boiling at room temperature. Because of the volatility of this agent, a new system was designed to contain, transfer, and vaporize it. The Tec 6 vaporizer is an injector, not a variable bypass type. Note that not all desflurane vaporizers are Tec 6 type. The Aladin desflurane cassette (Aisys) is a variable bypass vaporizer. |

|

|

Tec 6 operating principles. Click on the link to see the larger version.

|

|

Tec 6 alarm panel. Click on the link to see the larger version.

|

|

Tec 4 vaporizers. Click on the thumbnail, or on the underlined text, to see the larger version. Ohmeda Tec 4, 5 With the center vaporizer removed (if three are mounted side by side), one can activate both outer vaporizers simultaneously (in machines manufactured after 1995, this fault is corrected). Vaporizer outlet has check valve. |

|

Tec 5 vaporizers. Click on the thumbnail, or on the underlined text, to see the larger version. |

|

Sevotec 5 vaporizer (right). Click on the thumbnail, or on the underlined text, to see the larger version. The Sevotec 5 is used in a similar fashion to the other Tec 5 vaporizers. Note that sevoflurane may very well be safe at fresh gas flows of 1 L/m (or less) indefinitely, particularly when used with absorbents lacking strong bases.[15], [16], [17]

|

|

Penlon Sigma Delta sevoflurane vaporizer (right). Click on the thumbnail, or on the underlined text, to see the larger version. Penlon Sigma is similar to the Tec vaporizers, and can be found on either GE or Dräger machines.

|

|

Vapor 19.3 vaporizer. Click on the thumbnail, or on the underlined text, to see the larger version. Dräger Vapor 19.x is similar to Tec 4, 5: all are variable bypass types. The interlock on Dräger machines continues to function if any vaporizers are removed, but one must attach a short-circuit block to prevent leaks if any vaporizer is removed. There is no outlet check valve- the tortuous inlet arrangement protects from the pumping effect.

|

[1] Tilakaratna, P. How anaesthesia vaporisers work explained simply. At https://www.howequipmentworks.com/vaporisers/ Accessed Feb. 1, 2026

[2] Tilakaratna, P. Part 2: How anaesthesia vaporisers work explained simply. At https://www.howequipmentworks.com/part-2-vaporisers/ Accessed Feb. 1, 2026

[3] Tilakaratna, P. Advanced concepts of circle breathing systems explained. At https://www.howequipmentworks.com/vaporisers/ Accessed Feb. 1, 2026

[4] Seropian MA, Robins B. Smaller-than-expected sevoflurane concentrations using the Sevotec 5 vaporizer at low fill states and high fresh gas flows. Anesth Analg. 2000 Oct;91(4):834-6. doi: 10.1097/00000539-200010000-00013.

[5] Ehrenwerth and Eisenkraft Anesthesia Equipment 2nd ed 2013

[6] James MF, White JF. Anesthetic considerations at moderate altitude. Anesth Analg. 1984 Dec;63(12):1097-105.

[7] James MF, Hofmeyr R, Grocott MP. Losing concentration: time for a new MAPP? Br J Anaesth. 2015 Dec;115(6):824-6. doi: 10.1093/bja/aev151.

[8] Daniels D. Overfilling of vaporisers. Anaesthesia. 2002 Mar;57(3):288. doi: 10.1111/j.1365-2044.2002.2520_6.x.

[9] MacLeod DM, McEvoy L, Walker D. Report of vaporiser malfunction. Anaesthesia. 2002 Mar;57(3):299-300. doi: 10.1111/j.1365-2044.2002.2520_25.x.

[10] Rupani G. Refilling a Tec 6 desflurane vaporizer. Anesth Analg. 2003 May;96(5):1534-1535. doi: 10.1213/01.ANE.0000057768.66559.6E.

[11] Aziz E, Sanders GM. Failure of datex AS/3 anaesthesia delivery unit. Anaesthesia. 2000 Dec;55(12):1214-5. doi: 10.1046/j.1365-2044.2000.01798-3.x.

[12] MacArtney NJ, Cohen J. Another case of anaesthetic machine failure. Anaesthesia. 2000 Dec;55(12):1215. doi: 10.1046/j.1365-2044.2000.01798-5.x.

[13] Hendrickx JF, De Cooman S, Deloof T, Vandeput D, Coddens J, De Wolf AM. The ADU vaporizing unit: a new vaporizer. Anesth Analg. 2001 Aug;93(2):391-5 , 3rd contents page. doi: 10.1097/00000539-200108000-00031.

[14] Andrews JJ, Johnston RV Jr. The new Tec6 desflurane vaporizer. Anesth Analg. 1993 Jun;76(6):1338-41. doi: 10.1213/00000539-199376060-00027.

[15] Kennedy RR, Hendrickx JF, Feldman JM. There are no dragons: Low-flow anaesthesia with sevoflurane is safe. Anaesth Intensive Care. 2019 May;47(3):223-225. doi: 10.1177/0310057X19843304.

[16] Feldman JM, Hendrickx J, Kennedy RR. Carbon Dioxide Absorption During Inhalation Anesthesia: A Modern Practice. Anesth Analg. 2021 Apr 1;132(4):993-1002. doi: 10.1213/ANE.0000000000005137.

[17] ASA Committee on Equipment and Facilities. Statement on the Use of Low Gas Flows for Sevoflurane (2023). At https://www.asahq.org/standards-and-practice-parameters/statement-on-the-use-of-low-gas-flows-for-sevoflurane Accessed Feb 1, 2026